- Home

- Products

- Rice Polisher

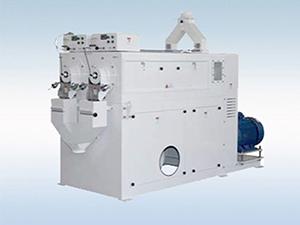

- Rice Polisher, SYX-CMS2 Rice Mill

Rice Polisher, SYX-CMS2 Rice Mill

White rice is obtained by removing the husks on brown rice. However, the resulting rice may still contain a small amount of bran powder, which will affect the rice appearance, quality and storage, resulting in a bad taste. By polishing and whitening the rice surface with the use of a rice polisher, both the appearance and taste are improved.

The machine has two polishing rolls with an upper and lower structure, allowing the rice polishing machine to be used in a parallel manner or in a series. It features a large output of 6-8 tons/hour when used in a series, a small floor area and a compact structure. The polishing roller is 1.2 meters long, though the total length when used in a series is 2.4 meters. The resulting polished rice is white and bright, and features a smaller breakage rate and less risk of forming a rice bran ball.

Output: 6-8T/H

Power: 75Kw

Dimension (L*W*H):2404*1430*2353mm

Weight: 2350Kg

Parallel polishing process: There is a single hoist feeding process required for each individual polishing roll to ensure the final output levels are as expected.

Advantages: Two rolls of rice can be polished at one time, ensuring a large output.

Series polishing process: Two elevators are needed. The material is first fed by one elevator and then transferred to the second roller through the use of a second elevator.

Advantages: The polishing process generally requires 2 to 3 polishing rounds, and when using this equipment as part of a series, a single machine can carry out both rounds, saving both equipment costs and floor space.

- The double roller polishing equipment's output ranges between 6 to 8 tons/hour, thus ensuring a high efficiency.

- All parts of the polishing system are made of food grade stainless steel, which is both sanitary and durable, resulting in an attractive white, polished rice.

- The SYX-CMS2 rice polisher is suitable for long and short grain varieties, making it applicable to long term, stable production and reducing the risk for rice bran balls.

- Because the rice polishing machine has two polishing rolls, users can choose between series polishing or parallel polishing. Series polishing requires that one roller will polish at a time, ensuring a better polishing effect. Parallel polishing means that material is polished by both rolls simultaneously, ensuring a larger output. Output through series use is 5 to 7 tons/hour, and the parallel output range is 8-12 tons/hour. Parallel polishing is also suitable for multi-machine polishing.

- Users can choose a 45kW or 55kW motor based on their requirements.

Sifly Agro-Tech Co.,Ltd.

Contacts: Cheng Fei

Fax: +86 551-65554921