Weigh Filler

Weigh Filling Machine, Packaging Machine

The weigh filler is designed for the weighing and packaging processes for grain. It supports a variety of packaging, including regular heat seal packaging, woven bag packaging, vacuum packaging, and sack bag packaging.

Features

- Special structure design

This design ensures a stable machine operation, and the sealed design of the weighing chamber effectively prevents dust from entering, thus protecting interior components. The double cylinder structure improves the cylinder stability and service life. - Alarm system

The weigh filler is equipped with a smart alarm system. When there is a fault or the weight is inaccurate, the machine will automatically alarm. - Optional devices

The weigh filler supports different sealing types, including a heat seal or suture. It is an intelligent machine that can connect to various networks to ensure users can monitor the production status in real time. It is equipped with a CO2 inflation device to inflate CO2 gas into the packaging and prolong product shelf lives.

Specifications

| Model | SYC-DCS-50FB3 | SYC-DCS-50FE-B | SYC-DCS50-1 | DCS-ZKBY |

| Packaging Type | Regular heat seal packaging | Regular heat seal packaging | Woven bag packaging | Vacuum packaging |

| Weighing Range (Kg) | 5-50 | 10-50 | 40-50 | 0.25-5.0 |

| Weighing Error | 0.1% F.S | 0.1% F.S | 0.2% F.S | ±0.2%F.S |

| Weighing Speed (Bag/h) | 600-1000 | 420-920 | 100-180 | 300(Six-sided) 240(Two-sided) |

| Power(kW) | 1.1 | 1.3 | 1.1 | 2.5 |

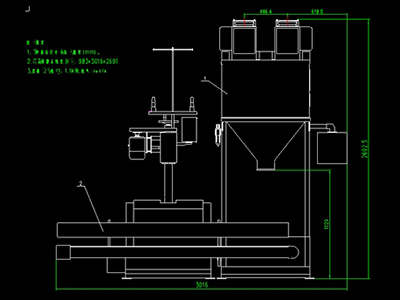

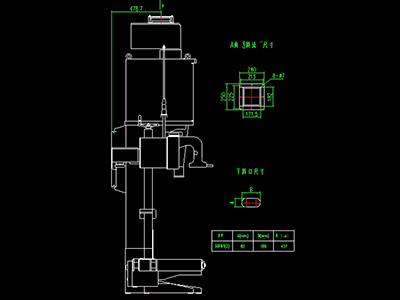

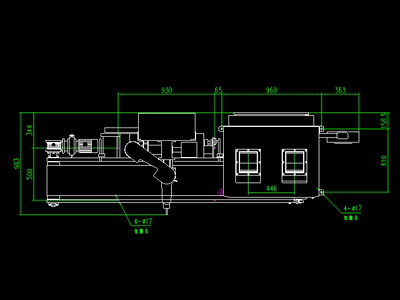

| Dimensions (L*W*H)(mm) | 3081*953*2691 | 3600*1100*3200 | 2810*1340*3075 | 1420*1460*2240 |

Working Principle

The weigh filler consists of a feeding system, weighing system, body frame, control system, conveyor and sewing machine. The packing bag should be manually put into the feed opening. After pushing the button, the cylinder will pinch the packing bag while raw materials are filled in the bag to the desired weight. The packing bag will then be sealed.

The weigh filler is suitable for granular materials such as rice.

Core Components

Heat sealer

Heat sealer CO2 inflation device

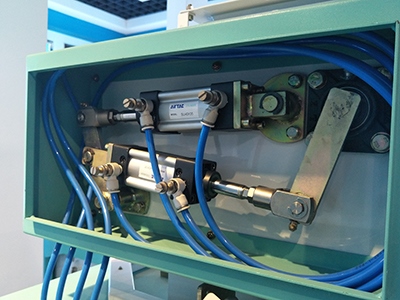

CO2 inflation device Cylinder

Cylinder

Samples

Woven bag packaging

Woven bag packaging Woven bag packaging

Woven bag packaging Regular heat seal packaging

Regular heat seal packaging Vacuum packaging

Vacuum packaging

Structure Diagram

Other products