- Home

- Products

- Grain Weight Bagging Machine

- Semi-Automatic Packing Machine

- Digital Weight Bagging Machine

Digital Weight Bagging Machine

Introduction

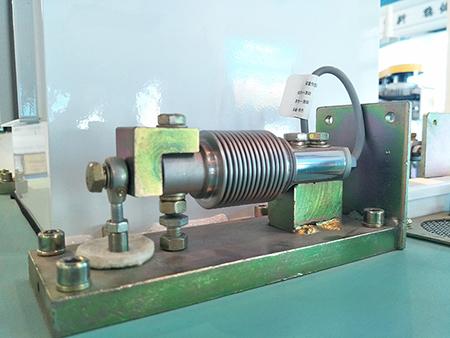

The digital weight bagging machine is used for automatic packaging of granular materials such as rice, grains, peanuts, soybeans and more. The entire weighing process is computer controlled, and automatically completed. The bagging machine features two feeding ports and two weighing cylinders, with a fast, labor saving weighing speed. The double cylinder structure improves both the service life and stability of the cylinder.

The core components include the weighing system, feeding system, body frame, control system, conveyor and sewing machine.

Parameter

| Model | DCS-15FB3 | DCS-50FB3 |

| Weighing range | 0.5-15kg | 5-50kg |

| Weighing error | 0.1% F.S | 0.1% F.S |

| Weighing speed | 800-1400Bag/h | 600-1000Bag/h |

| Power | 1.1Kw | 1.1Kw |

| Dimension (length * width * height) | 2873*754*2330mm | 3081*953*2691mm |

Features

- The weighing cylinder on the digital weight bagging machine is suspended by 3 sensors. Compared to a traditional single sensor suspension, this method improves the interference resistance, as well as the stability for high speed, continuous weighing.

- The digital weight bagging machine features a closed working chamber in order to prevent dust and other contaminants from entering and affecting the components and bagging materials.

- The weight bagging machine will carry out real time monitoring, and alarm when weight amounts are inaccurate.

- The digital weighing and bagging machine will transmit data to a computer or cell phone through the use of a CDMA 3G or 4G network.

- It features a multi-functional sewing bag, and can switch to ordinary sewing or heat sealing through a simple rotation.

- The bagging machine is equipped with an aeration device to uniformly push carbon dioxide into the bag and extend the shelf life of the packaged materials.

Finished Products

Inquiry

Sifly Agro-Tech Co.,Ltd.

Contacts: Cheng Fei

Fax: +86 551-65554921